Step 6 - Calibration

Time required

15-30 min depending on how often you have to repeat the calibration print.

Overview

There are three basic steps: Checking/tuning the docking position, adjusting the z-offset, calibating the x/y offset.

Cheat sheet

As the Mark2 community increases there's a lot of helpful comments from new users. A good point to start from is Chiz' cheat sheet.

First we check the docking position.

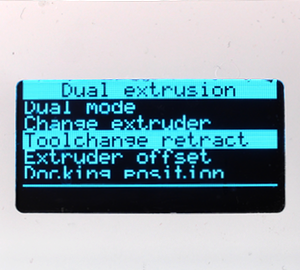

Goto the dual-extrusion menue and select "Docking position".

Select "Move". The head will move to the default docking position.

Depending on the exact position of the endstops of your Ultimaker you might have to fine tune the docking position.

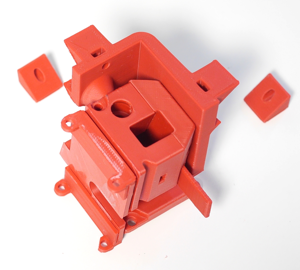

The left pair of magnets should slightly touch as the parked head will already tilt a little when the magnets are in reach. There should be approx. 1 mm gap between the right pair of magnets. The angled tab on the right side should be close enough to push the parked head out of the dock. The parked head must by no means get jammed between the coupling and the dock.

Use the menue to change X and Y in case.

Check the bowden tube curvature. We want a nice, smooth curve.

The docking process is quite robust to any tilting forces applied by the bowden. However to make it run as smooth and silent as possible, make sure the parked head is not heavily tilted or jammed.

Perform a series of tool changes using the "Change extruder" menue.

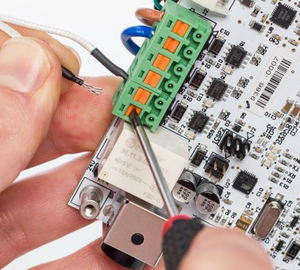

Next, switch to Extruder 2. Then select "Adjust Z (nozzle 2)".

Turn the wheel until the nozzle touches the build plate. Hit "store"

Calibration print

Important

Please check that the Y value in the wipe position menue is 25 mm or greater. Even without using a wiping device thiss will affect the priming position after a tool change.

Get the calibration print gcode file from Github.

Obviously the printbed has to be properly calibrated.

Load both extruders with standard PLA filament and print.

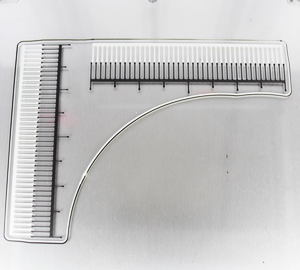

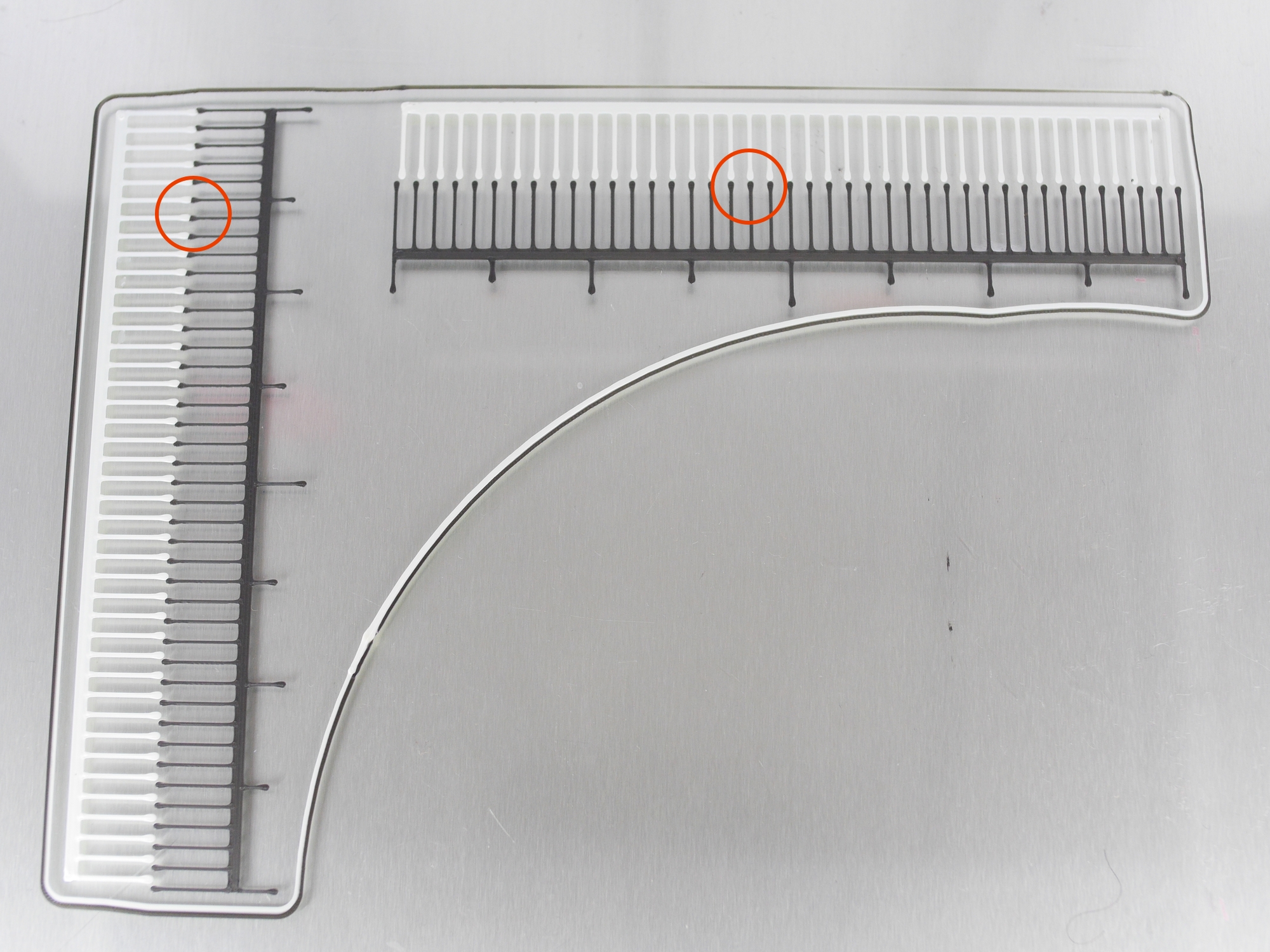

Look for the aligned dual material X and Y lines on the calibration print.

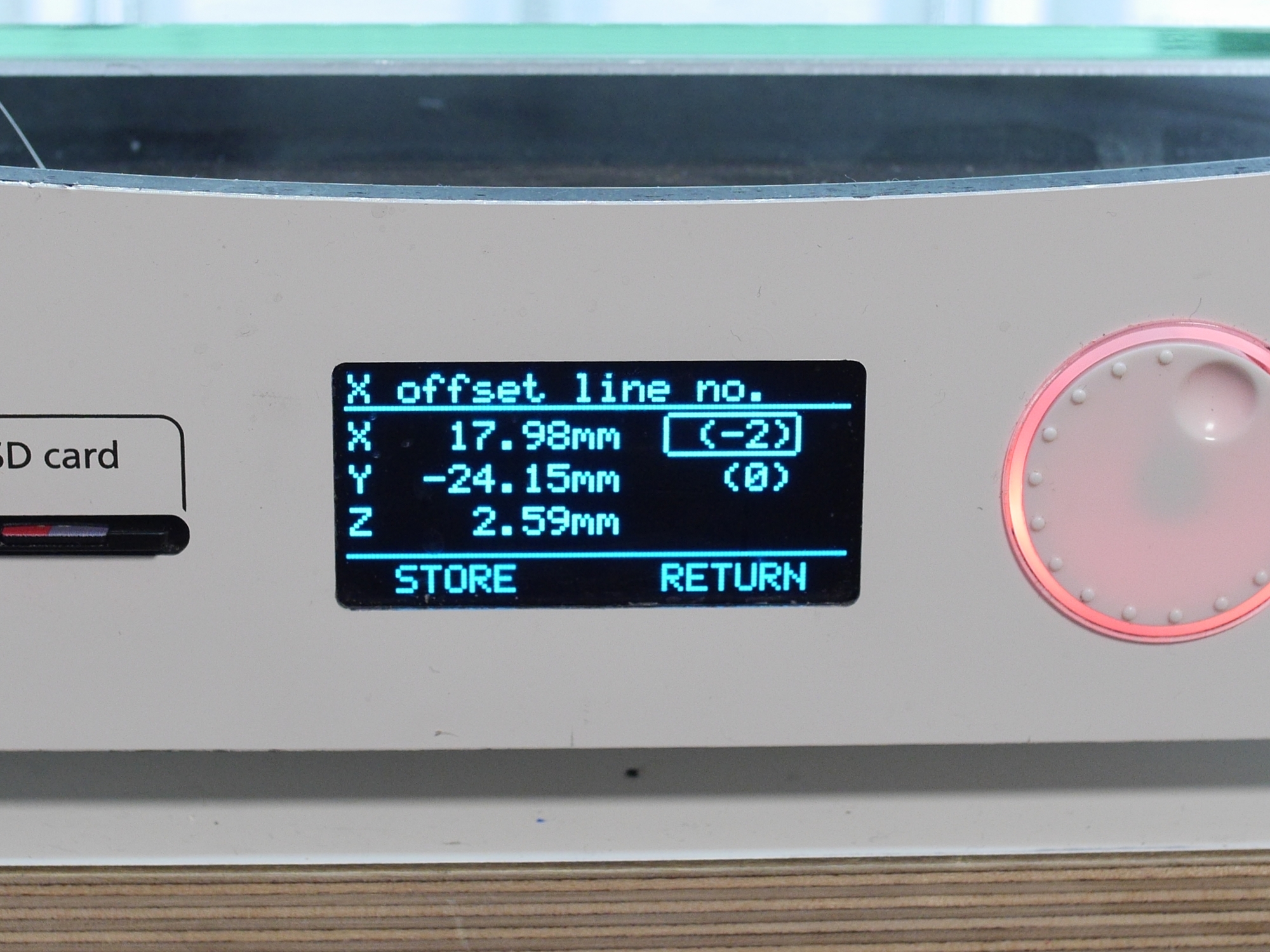

Open the extruder offset menue.

Insert the matching number in the input field on the display.

There seems to be a rounding error in the current firmware. Therefore we strongly recommmend to round the x/y offset to a multiple of 0.05 mm.

Same for Y.

Hit "store".

It's a good idea to repeat the calibration print and check again, especially if your offsets were way off.

Your very first try can even be off in a way that no lines match. In this case use a ruler to get a rough estimate, adjust X and Y and repeat the calibration print.