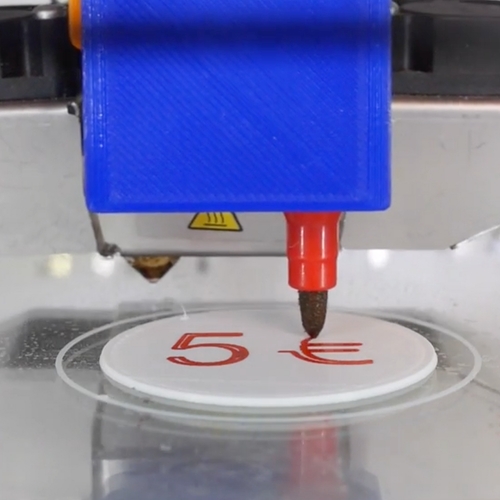

Ok, but what's the secret?

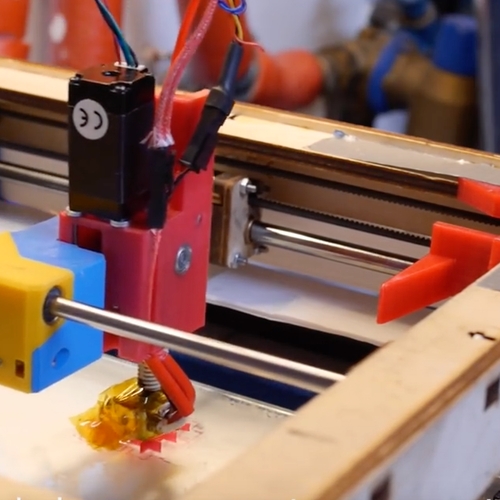

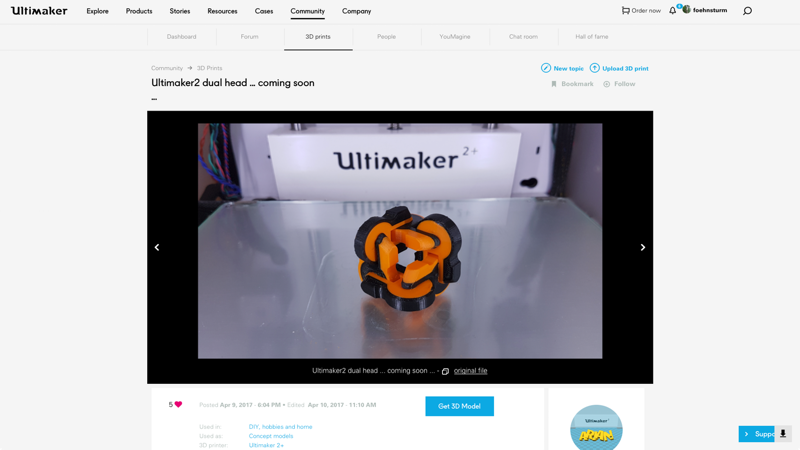

Mark2 is an Ultimaker community project, initiated by foehnsturm (alias wokbrenner on youtube). Got some time and want to know the full story? Skim through the huge "A different multi-extrusion approach" thread, where all started (1200+ posts ...).

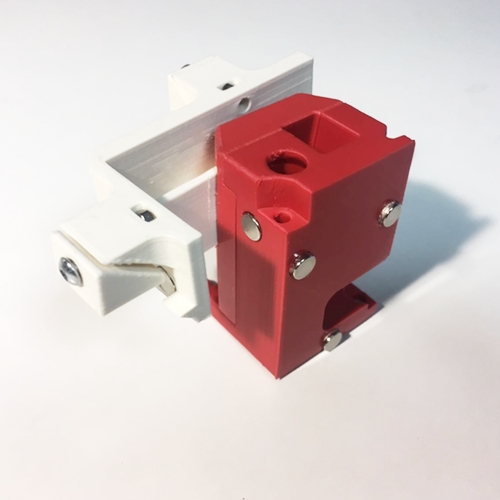

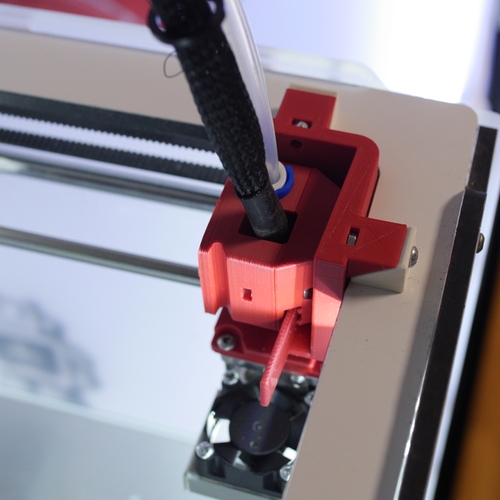

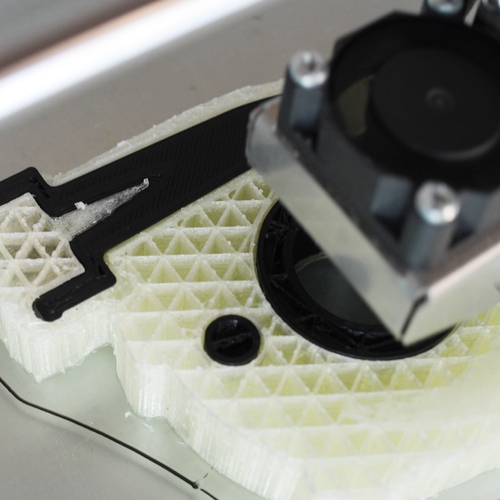

The magnetic tool changer has been developed and optimized for over 2 years now and proved it's reliability and printing quality with more than 10.000 hrs of printing (corresponding to some 2.000.000 tool changes).

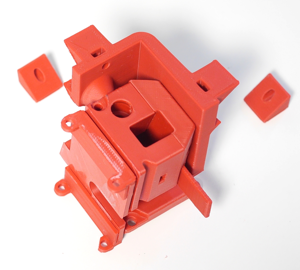

Everything is published on Github. Your additional investment, besides a second drive train? Not more than €/$ 50 and one day of labour. Sounds good, doesn't it?